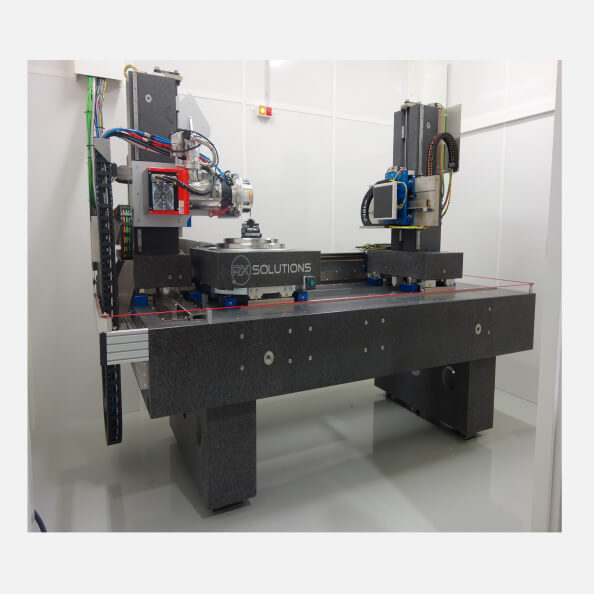

Flexible, Industrial, Computed Tomography Products

CT Solutions for Manufacturing Challenges

- Dimensional Metrology: GD&T, Linear dimension, CAD comparison and color mapping

- Material and Structural Analysis: Additive part lattice structures

- Defects analysis: Porosities, inclusions and void detection

Industries

Medical & Dental Aerospace Automotive Composite Electronics Injection Molding Military & Defense Oil & Gas Plastics Additive Manufacturing Academic & Research Centers Arts & Jewels

On Demand Contract Services

Applications & Case Studies

Maximize the Power of X-Ray Technology in Academic & Scientific Research

Industrial Computed Tomography (CT) is powerful technology that digitally peels back the layers of a specimen to create a 3D model without causing any physical damage. Its non-destructive properties have led museums, life science, paleontology, and geology fields to adopt the technology to study delicate materials, historical artifacts, and valuable samples. X-ray for Life Sciences…

Is Industrial CT the Inspection Method for You?

One of the challenges facing manufacturing quality control teams from all industries is knowing what to inspect on their parts and how to inspect them. It can be difficult to know what element of a part is causing failure when you can’t see or assess it with traditional inspection methods. From vision systems to CMMs…

Complex Assembly Inspection with Computed Tomography

Unlike other methods of inspection and non-destructive testing, X-ray tomography is not limited by part geometry and composition. It has the capability to reveal hidden features in complex parts and parts assembled from multiple components without disassembling and inspecting each individually. Comprehensive Analysis and Results To avoid part failure, X-ray tomography can be used to…

Advancements for Medical Technology Part Inspection

Evolving medical technologies have led to new devices that are held to an increasingly high standard in the design, development, and testing processes. Millions of people worldwide depend on insulin pens, implantable devices, heart stents, and capsules to live. There is no room for error when human lives depend on the success of a medical…

Composite Analysis with X-Ray Tomography

Composites, being the product of two or more constituent materials, all vary in their chemical and physical structures. This variance makes composite materials ideal for use in many industrial fields, but requires inspection during the production process. The technology behind CT metrology provides a clear solution for seeing inside composites to make sure they will…

Integrating Computed Tomography into Product Development

Product development can be a lengthy process, even if you’re building on an already existing product. By the time your product is ready to go, you’ve put considerable effort, time and money into making it just right. But how do you know if it’s as right on the inside as it looks on the outside?…

Inspecting Complex Aerospace Parts with X-Ray Tomography

In the aerospace industry, it is critical that all parts and products pass inspection without any doubt in the precision and accuracy of their configuration. X-ray tomography is an effective and efficient tool for verifying product quality and safety without damaging the part. Companies in the aerospace industry often run into product quality issues, mainly…

3D Printing – Additive Manufacturing

Additive manufactured workpieces require many controls and inspections during the overall production process. Computed tomography (CT) is a powerful non‑destructive technology to inspect every samples in an easy way and the only one giving the ability to see inside the matter.

Composites Material & Fibers

Composite workpieces require many controls and inspections during the overall production process. Computed tomography (CT) is a powerful non‑destructive technology to inspect every samples in an easy way and the only one giving the ability to see inside the matter.

Foundry and Welding

Foundry components require many controls and inspections during the overall production process. Computed tomography (CT) is a powerful non‑destructive technology to inspect every samples in an easy way and the only one giving the ability to see inside the matter.

After Sales Support

The technical support you need, any time, any where. We provide quick remote support, preventative maintenance solutions, onsite repairs and installations, replacement components, system relocations and more.

Call. Text. Email. Our team of engineers are ready to help.